Introduction

LED strip lights have revolutionized the way we improve our spaces. From accent lighting in modern kitchens to mood lighting in cozy bedrooms, these versatile strips are sleek, energy-efficient, and relatively easy to install. But one of the most common questions for DIYers and professionals alike is: Can you bend LED strip lights? And if so, how far can you bend them without causing damage?

Let’s explore the limits of bending LED light strips and unpack the potential drawbacks of improper handling.

What Are Flexible LED Strip Lights?

- Flexible PCB (Printed Circuit Board): The backbone of the strip, allowing it to curve and adhere to various surfaces.

- LED Chips: Spaced evenly across the strip, determining brightness and color.

- Resistors and Drivers: Regulate current and protect the LEDs.

- Adhesive Backing: Usually 3M or similar, for easy mounting.

- Silicone Coating (Optional): Adds water resistance and durability.

Can You Bend LED Strip Lights?

- Bending Directions: Lateral vs. Vertical

- Lateral (side-to-side) bending: Safe and intended by design.

- Vertical (up-and-down) bending: Dangerous and often leads to PCB cracking.

Best Practices for Bending LED Light Strips Safely

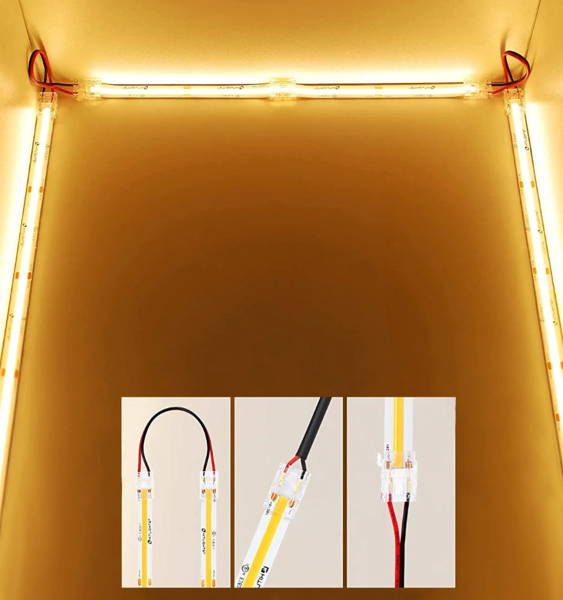

Use a cable jumper connection for bending your strips around a corner extending them across a gap or connecting them to a power supply or dimmer.

To What Extent Can You Bend Them?

- Standard Flexible LED Strips: Allow modest lateral bends.

- COB (Chip-on-Board) Strips: More densely packed, often less flexible.

- Neon Flex Strips: Specifically designed for ultra-smooth curves and bends.

- Thicker PCBs are more durable but less flexible. Thinner boards bend easier but are prone to damage under stress.

- Curved furniture edges: Usually safe with mild curves.

- Vehicle interiors: Use ultra-flex strips or segment the layout.

- Architectural arches or columns: Choose specialized curved LED products

The Consequences of Improper Bending

Conclusion

- Follow the manufacturer’s bending radius guidelines.

- Use accessories for corners and tight curves.

- Consider alternatives like neon flex or segmented connections for complex shapes.