Introduction

One of the most important yet often overlooked LED specifications is LED strip density. Whether it is for accent lighting for a cozy living room, planning task lighting under kitchen cabinets, or creating eye-catching retail displays, understanding LED density can make or break the effectiveness of your setup. So what does LED density mean, and how do you choose between standard-density and high-density LED strips?

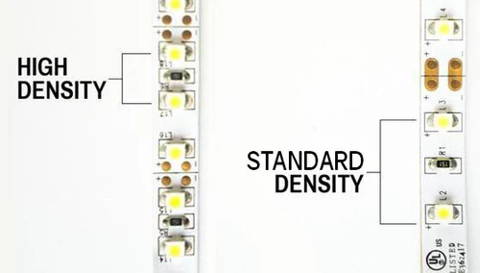

What Is LED Strip Density?

- Standard-density LED strip: 30 or 60 LEDs/m

- High-density LED strip: 120 LEDs/m or more

High-Density vs. Standard-Density LED Strips

| Feature | Standard-Density LED Strip | High-Density LED Strip |

| LED's per meter | 20-60 | 120-240 |

| Brightness | Moderate | High |

| Light uniformity | Visible dots | Smooth, continuous light |

| Power consumption | Lower | Higher |

| Cost | More budget-friendly | Premium price |

|

Ideal for |

Accent lighting, decorative use | Task lighting, indirect lighting, and commercial projects |

Why LED Strip Density Matters

- A 60 LEDs/m 5050 strip can output around 700–1000 lumens per meter.

- A 120 LEDs/m 2835 strip might reach 1800+ lumens per meter, depending on voltage and quality.

- You’ll need a larger power supply.

- Heat buildup becomes a concern, especially in enclosed spaces.

Choosing the Right Density for Your Project

Understanding LED Types and Spacing

| Chip Type | Size | Output Range | Notes |

| 3528 | 3.5x2.8 | Low–Moderate | Ideal for low-density, cost-effective strips |

| 5050 | 5.0x5.0 | Moderate–High | Can contain 3 diodes per chip, very bright |

| 2835 | 2.8x3.5 | High efficiency | Used in many high-density strips |

| 5630/5730 | 5.6x3.0 / 5.7x3.0 | Very high output | Requires more heat management |

LED Spacing:

In a 60 LEDs/m strip, LEDs are spaced about 16.6mm apart. For 120 LEDs/m, that distance drops to ~8.3mm. Smaller spacing creates smoother, more uniform lighting.