Introduction

LED strip lighting has become a go-to solution for various applications, from architectural accents to retail displays and home installations. However, one often-overlooked factor that directly impacts the longevity and reliability of these lighting systems is the choice of adhesive. Selecting the right adhesive is crucial to ensure a secure bond, prevent premature detachment, and maintain an aesthetically pleasing installation.

Types of Adhesives for LED Strips

Characteristics: Low surface energy, high shear strength, quick adhesion

Applications: Ideal for temporary or semi-permanent installations on non-porous surfaces

Examples: 3M 4941, Tesa 60762

2. Liquid Adhesives

Characteristics: High bonding strength, versatile applications, requires curing time

Applications: Permanent installations on rough or porous surfaces

Examples: Loctite Titebond II, Gorilla Glue

3. Structural Adhesives

Characteristics: Exceptional bonding strength, excellent weather resistance, requires specialized application

Applications: Heavy-duty installations, extreme environments, and critical applications

Examples: Epoxies, Urethanes, Acrylics

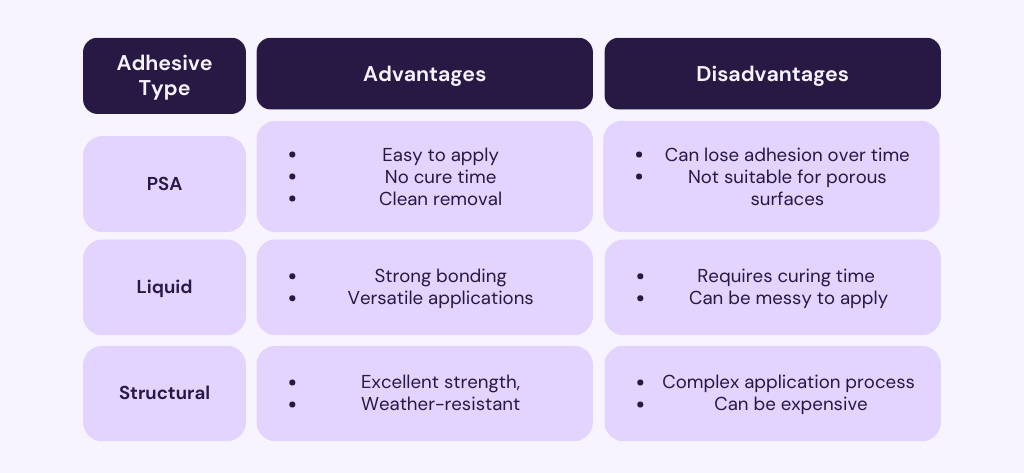

Advantages and Disadvantages of Adhesive Types

Factors to Consider When Choosing an Adhesive

- Surface Material:Different adhesives bond better to certain materials like glass, metal, or plastic.

- Installation Environment: Factors such as temperature, humidity, and UV exposure affect adhesive performance.

- Application Method: Choose an adhesive that aligns with your preferred application method (e.g., roller, brush, spray).

- Durability Requirements: Determine the lifespan required for the installation.

-

Cost: Adhesives vary in price depending on their performance and composition.

Best Practices for Applying Adhesives to LED Strips

- Surface Preparation: Clean the surface thoroughly to remove dust, dirt, and oils.

- Even Application: Apply adhesive evenly to avoid weak spots.

- Firm Pressure: Press the LED strip firmly into place to enhance bonding.

- Curing Time: Allow the adhesive to cure as per the manufacturer’s instructions for optimal results.

Troubleshooting Adhesive Issues

- Poor Adhesion: Ensure proper surface preparation, adhesive selection, and cure time.

- Residue Issues: Use an appropriate adhesive remover and follow cleaning guidelines.

- Durability Problems: Upgrade to a stronger adhesive or incorporate mechanical fasteners for extra support.