Introduction

Power supplies are key in a wide range of uses, from simple LED strip lights to complex industrial equipment. However, environmental factors such as heat and moisture can significantly impact their performance and noise levels. These factors influence the longevity and efficiency of power supply components, including dimmable drivers and transformers. Understanding how environmental conditions affect power supplies can help users make informed decisions for their lighting and electrical setups, ensuring longevity and reliability.

How Heat Affects Power Supply Performance

- Voltage Regulation Issues: High temperatures can cause fluctuations in voltage output, potentially damaging sensitive LED strip lights.

- Thermal Derating: Many power supplies have thermal derating curves, meaning their output capacity reduces as temperatures rise.

- Component Degradation: Prolonged exposure to heat can shorten the lifespan of capacitors, resistors, and other internal components.

- Fan Noise: Overworked cooling fans in dimmable drivers and power supplies contribute to increased operational noise.

- Component Vibrations: Expanding materials in high-heat conditions can cause transformers to vibrate, creating a humming sound.

- Electrical Noise: Heat-related inefficiencies may introduce additional electrical noise, impacting the quality of LED strip lighting and other connected devices.

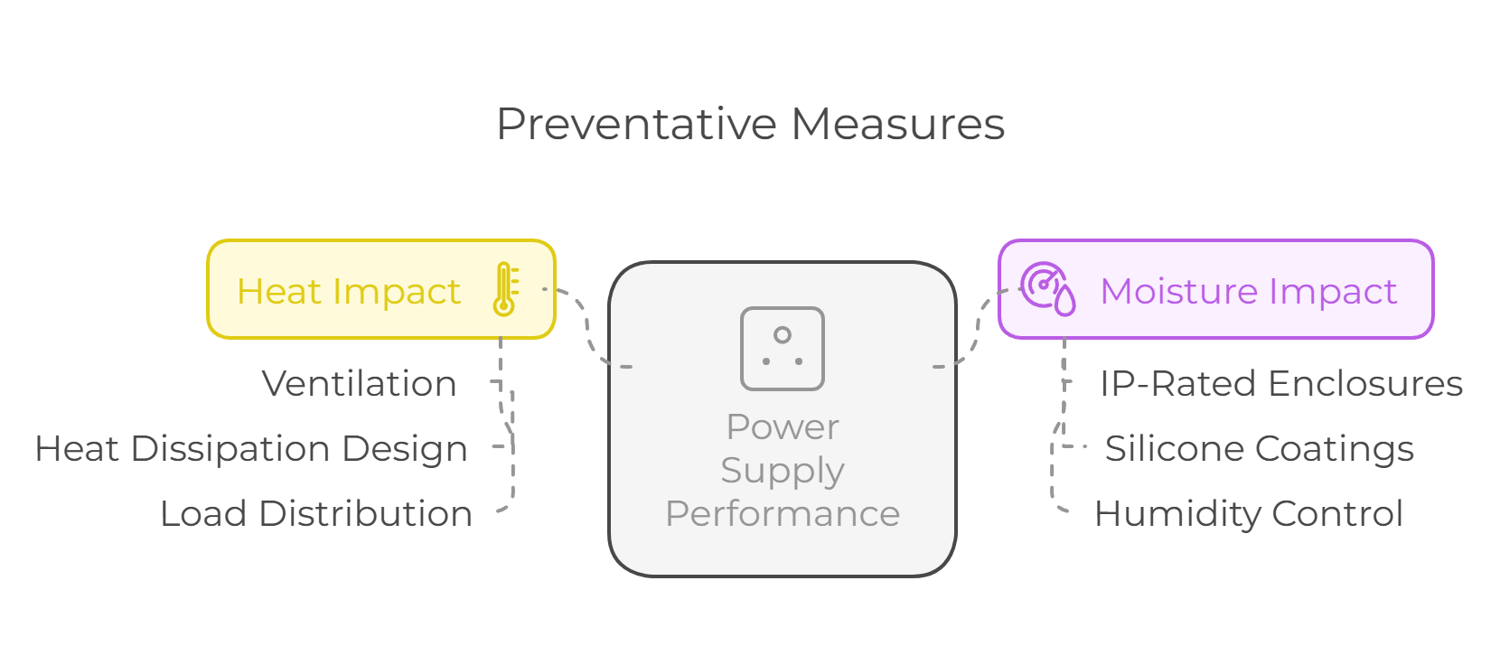

- Adequate Ventilation: Ensure sufficient airflow around power supplies to prevent overheating.

- Heat Dissipation Design: Use power supplies with built-in heat sinks or cooling systems.

- Proper Load Distribution: Avoid overloading transformers or dimmable drivers, as excessive demand increases heat output.

How Moisture Impacts Power Supply Performance

- Water Ingress in Outdoor Applications: LED strip lights used in outdoor or damp environments are at risk if power supplies are not properly sealed.

- Internal Condensation: Sudden temperature changes can cause condensation inside power supplies, leading to short circuits and component damage.

- Rust and Material Degradation: Moisture exposure weakens metallic components, leading to compromised electrical conductivity.

- Arcing and Crackling Sounds: Water presence may cause arcing, leading to irregular electrical noise.

- Buzzing in Transformers: Damp conditions can alter the magnetic properties of transformers, increasing buzzing sounds.

- Dimming Inconsistencies: Dimmable drivers exposed to moisture may experience flickering or inconsistent brightness levels in LED strip lights.

- IP-Rated Enclosures: Use power supplies with high Ingress Protection (IP) ratings for outdoor and humid environments.

- Silicone Coatings: Apply protective coatings to sensitive components to prevent corrosion.

- Humidity Control: Maintain stable indoor humidity levels to prevent condensation inside power supply units.

Best Practices for Ensuring Reliable Power Supply Performance

- Temperature Ratings: Select power supplies with high thermal tolerance.

- Moisture Resistance: Choose units with protective coatings and high IP ratings for humid environments.

- High-Quality Components: Opt for power supplies with durable capacitors and robust insulation to withstand environmental stressors.

- Avoid Overloading: Running a power supply at its maximum capacity generates excess heat. Opt for a unit with at least 20% headroom above the required load.

- Ensure Proper Ventilation: Place power supplies in well-ventilated areas to prevent overheating.

- Regular Inspections: Check for dust buildup, corrosion, or signs of overheating to prevent long-term damage.

- Cooling Fans and Heat Sinks: Improve heat dissipation in high-temperature conditions.

- Weatherproof Enclosures: Protect power supplies from moisture and dust ingress.

- Voltage Regulators and Surge Protectors: Prevent voltage fluctuations that may exacerbate environmental stress.